| Comparison of Forged Aluminum Wheels and Steel Wheels |

| Release time:2023-12-01 22:29:56 | Views: |

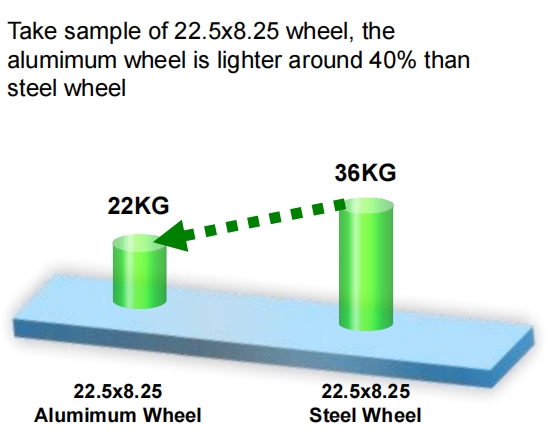

The pressure on the environment and energy around the world is increasing. In order to continuously meet the requirements of environmental protection and reduce costs, automobile manufacturers are applying various advanced technologies to make the weight of automobiles lighter and lighter. Europe's special-purpose vehicle design and manufacturing level is world-leading, and its lightweight pace is at the forefront of the world. The inner and outer plate materials of the van semi-trailer, the urban aluminum alloy are also selected for the dump truck and the cement mixer truck, which greatly increases the carrying capacity of the professional vehicle products. According to reports, it is also a 10-ton cement mixer truck, and the weight of the vehicle using light top-loading material is more than 2 tons lighter than that of the traditional top-loading material.

As we all know, long driving time will cause the temperature of tires and brake pads to rise, and the temperature rise is likely to cause spontaneous combustion, which is also one of the fuses of many spontaneous combustion events in summer vehicles. The good heat dissipation performance of aluminum alloy can reduce the temperature of tires and brake pads, thereby reducing the "eat tire" of the front tire by more than 50%, and extending the mileage of the tire by about 30%. Strength test The pressure required to deform the wheel by 5cm is 71,200 kg for the aluminum alloy wheel and 13,600 kg for the steel wheel. It can be seen that the strength of the aluminum alloy wheel is 5 times that of the steel wheel.

Impact test The pressure required to deform the wheel by 5cm is 71,200 kg for the aluminum alloy wheel and 13,600 kg for the steel wheel. It can be seen that the strength of the aluminum alloy wheel is 5 times that of the steel wheel.

The experimental results show that aluminum wheels can withstand greater pressure than steel wheels.

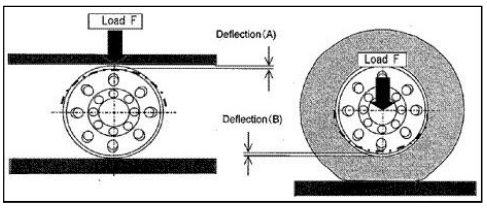

All-round precision machining for perfect roundness:Aluminium alloy wheels have minimal and uniformdeformation under load due to their high strength. As aresult, the rolling resistance is reduced, and the tire wear isuniform, which not only prolongs the service life, but alsomakes the driving more stable and safe. Such high strengthcan reduce the tilt of tires and hubs when the vehicle iscornering, more importantly, it can stabilize the vehicle'sdriving route under abnormal conditions and avoid thedanger of the vehicle tipping over!

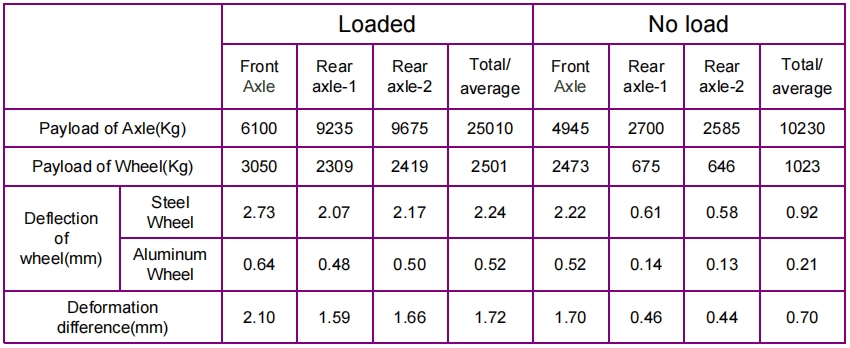

When the load is full, the average deformation of aluminum alloy wheels is 0.52mm, while the average deformation of steel wheels is 2.24mm. That is to say, at full load, aluminum wheels deform less than steel wheels. • Aluminium is 100% recyclable • Fuel efficiency: Forged aluminium wheels were fitted on a number of hybrid buses. The essential parameters were systematically measured and compared with buses fitted on steel wheels. Over the period of 6 to 7 months fuel savings of up to 1% on the hybrid buses. • CO2 reduction - Wheels bring down the carbon footprint of buses and commercial vehicles: Replacing 6 steel wheels with Wheels on a 2-axle diesel city bus brings down CO2 emissions by 3 tons over the 12 year lifetime of the bus and 750 000 km Replacing 10 steel wheels with Wheels on a 3-axle diesel articulated city bus brings down CO2 emissions by 5 tons over the 12 year lifetime of the bus and 750,000 km Replacing 12 steel wheels with Wheels on a 2-axle truck and 3-axle trailer brings down CO2 emissions by 4 tons over the lifetime of truck (2x5 years) and trailer (10 years) and 1,300,000 km • Give your vehicles an amazing look • Timeless design

|